Dugdale Bros shortlisted for Export Award

The strong growth of our presence in overseas markets is something we’re very proud of, so we’re delighted to have been named as a finalist in the Huddersfield Examiner Business Awards 2018’s ‘Export Award’ category.

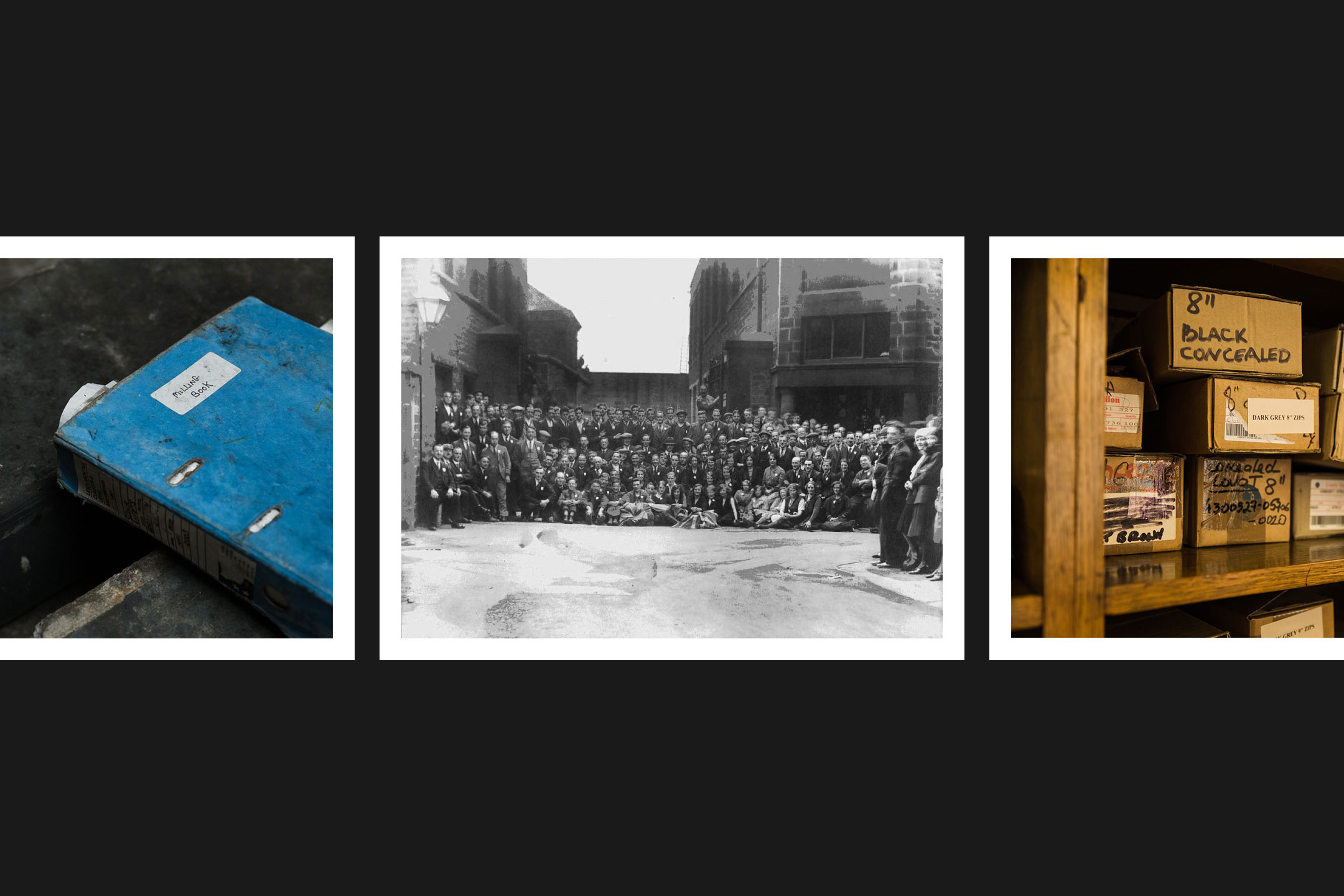

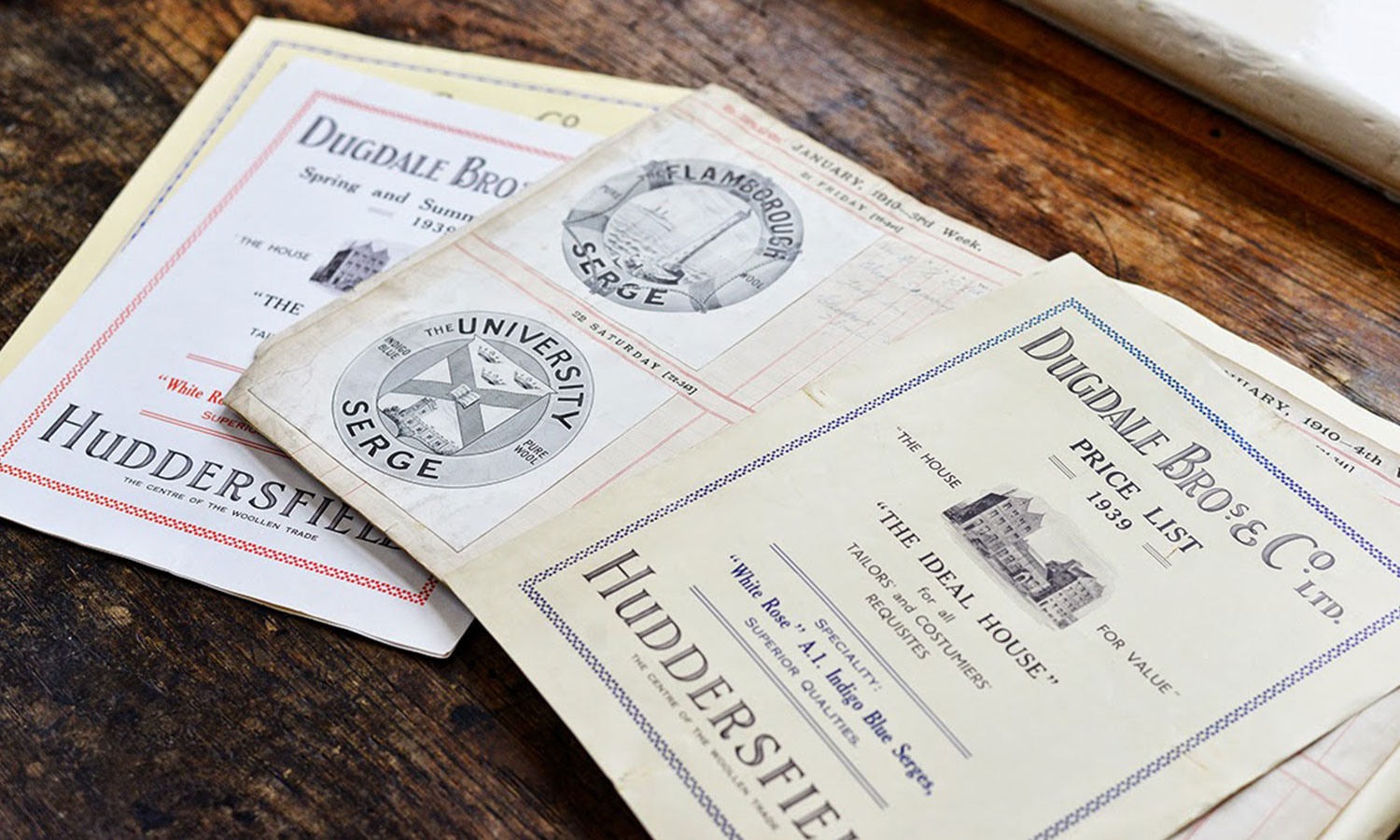

Having called this West Yorkshire town home since 1896, we seize any opportunity we can to celebrate its rich textiles heritage. In recent years, we’ve taken our ‘Made in Huddersfield’ cloth as far afield as South East Asia and Australasia, so the fact that we’ve been recognised as one of the best exporters in the area is a real honour.

With a thorough entry process – requiring companies to evidence a “substantial and sustained increase in activity outside of the region”, along with details of how national and international success has contributed to the local economy – we were certainly put through our paces in compiling our initial submission.

Thankfully, our promising figures, fascinating backstory and forward-thinking approach to international sales speak volumes, and we’ve been named as one of three finalists in this category – alongside Huddersfield Town FC and Distinctive Chesterfields.

As one of 12 accolades set to be presented, all shortlisted companies are set to be visited by a film crew as part of the next phase of judging. This footage will then be showcased at a black-tie awards ceremony – where the triumphant businesses will be revealed.

Set to take place at the John Smith’s Stadium on Thursday 1 November, we’ve already booked our table for the night and are eagerly awaiting the announcement of the winners…

Congratulations to all others that have been shortlisted – we’ll see you at the ceremony!