Exclusive Sydney Cricket Ground Blazer Project

Australia’s Sydney Cricket Ground (SCG) – one of the world’s most prestigious sporting venues – has collaborated with luxury UK cloth merchant Dugdale Bros & Co and leading made-to-measure tailors Oscar Hunt, for its exclusive club members’ jacket.

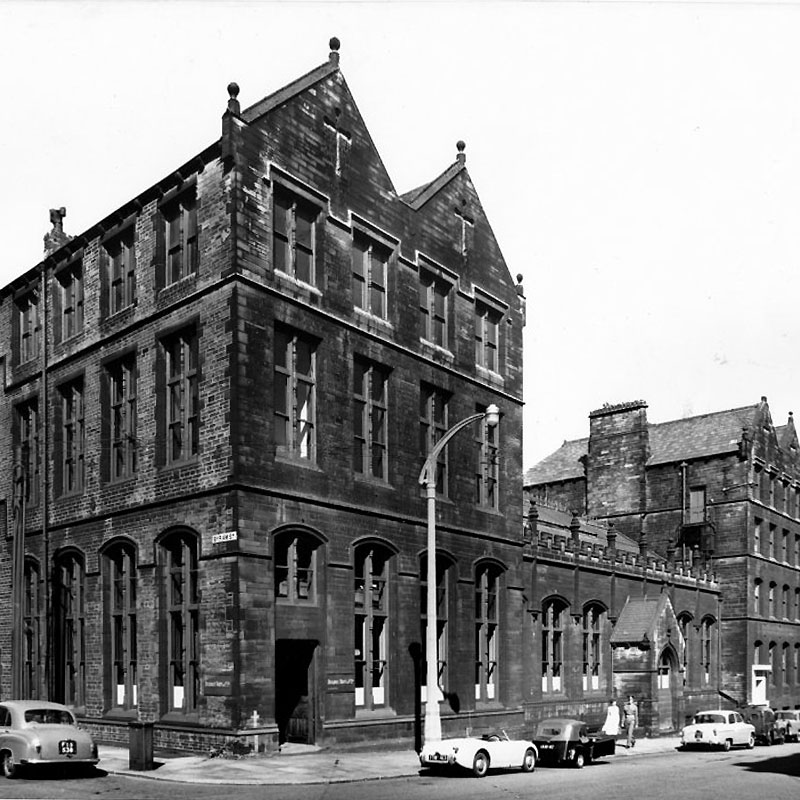

To date, several hundred metres of cloth have travelled the 10,500 miles (10,000 kilometres AUS media) from Huddersfield to the other side of the world, where it’s being transformed into made-to-measure blazers for SCG members.

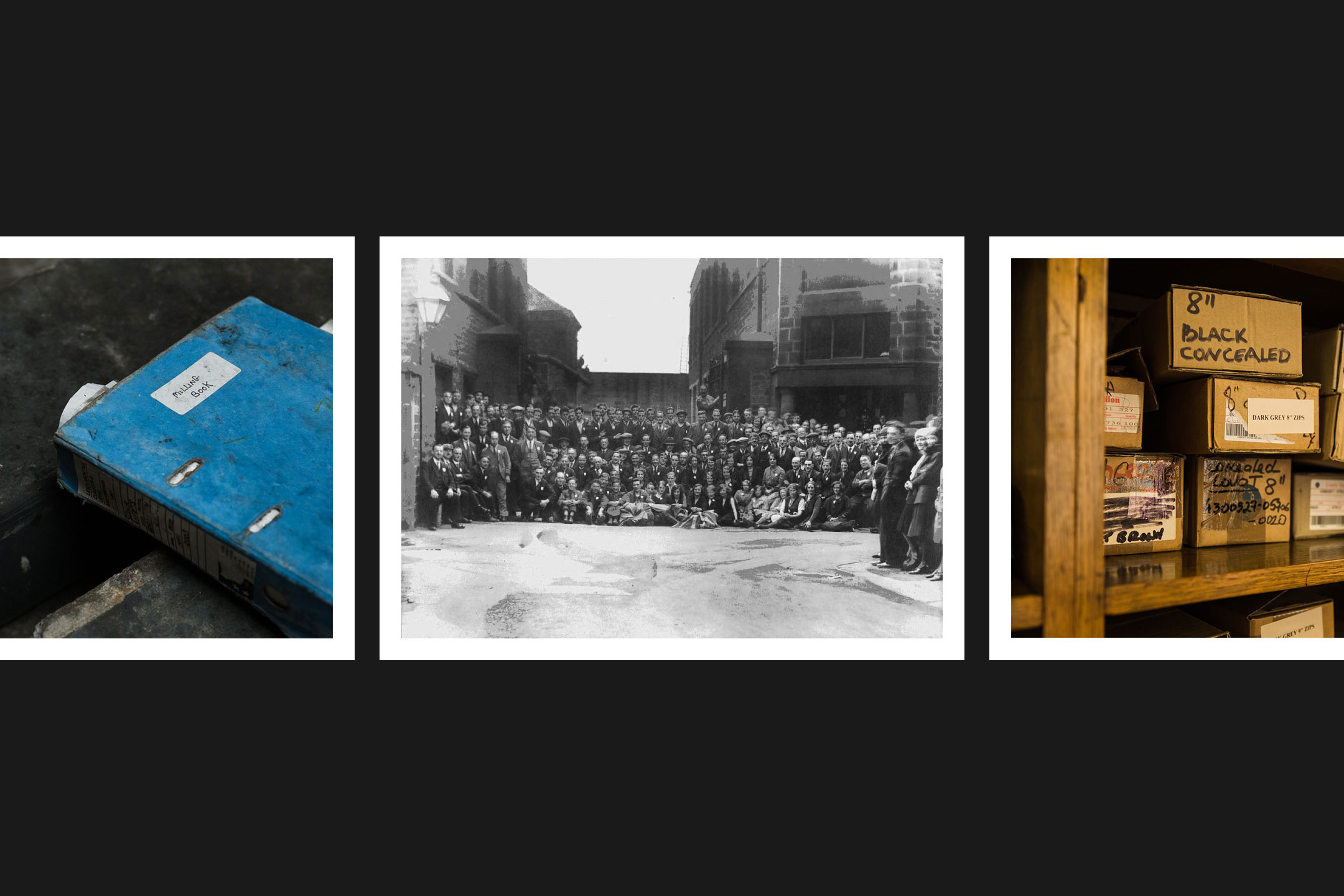

Huddersfield has a long connection to Australian sport as the birthplace of Northern union (rugby league) at The George Hotel. Rugby league began in New South Wales in 1908, and the SCG has hosted more top-level league than any venue in the world.

Sydney Cricket and Sports Grounds Chief Executive Officer, Kerrie Mather was delighted with the final garment design.

“The colours of the new SCG blazer are inspired by our Members and Ladies pavilions,” Ms Mather said.

Members of the SCG XI cricket team will wear their new SCG blazer on a two-week playing tour of England departing August 4, during which they will also attend the Ashes Tests at Lord’s and Headingley.

Oscar Hunt director Chris Edwards, said Dugdale Bros’ 123-year heritage made them the ideal partner in the blazer project: “SCG is steeped in sporting history and the Trustees wanted a cloth which reflected this level of heritage.”

“We were looking to source fabric capturing tradition and timeless craftsmanship – features not found in mass-produced textiles – and this aligned perfectly with the Dugdale Bros’ ethos.”

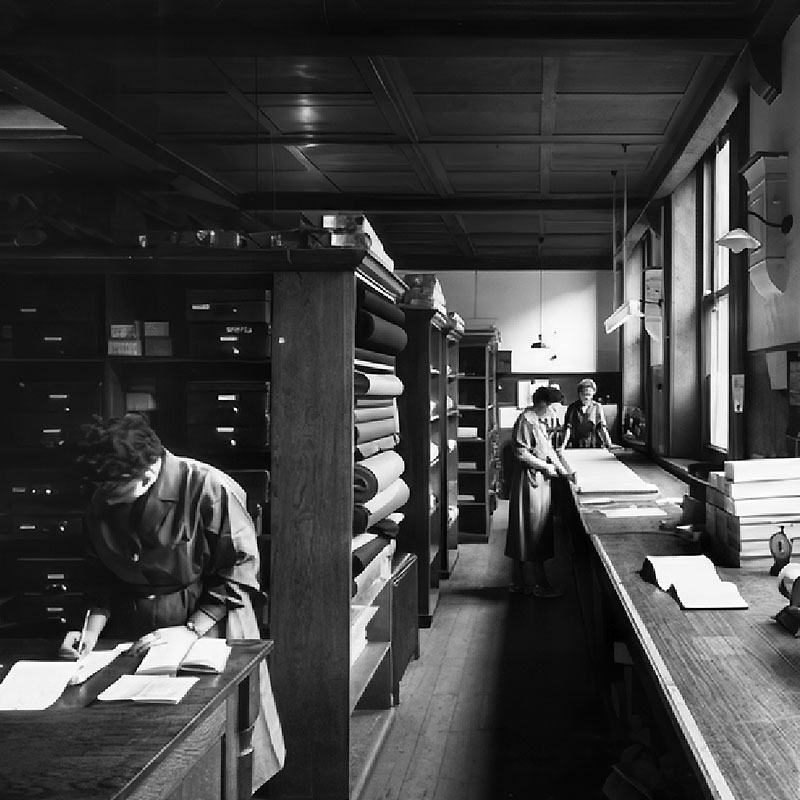

Managing director of Dugdale Bros, Simon Glendenning, added: “Our highly regarded ‘Made in Huddersfield, England’ selvedge means we work with tailors and fashion houses across the globe, and when we were asked to be involved in such a heritage-led project, it was the perfect fit.

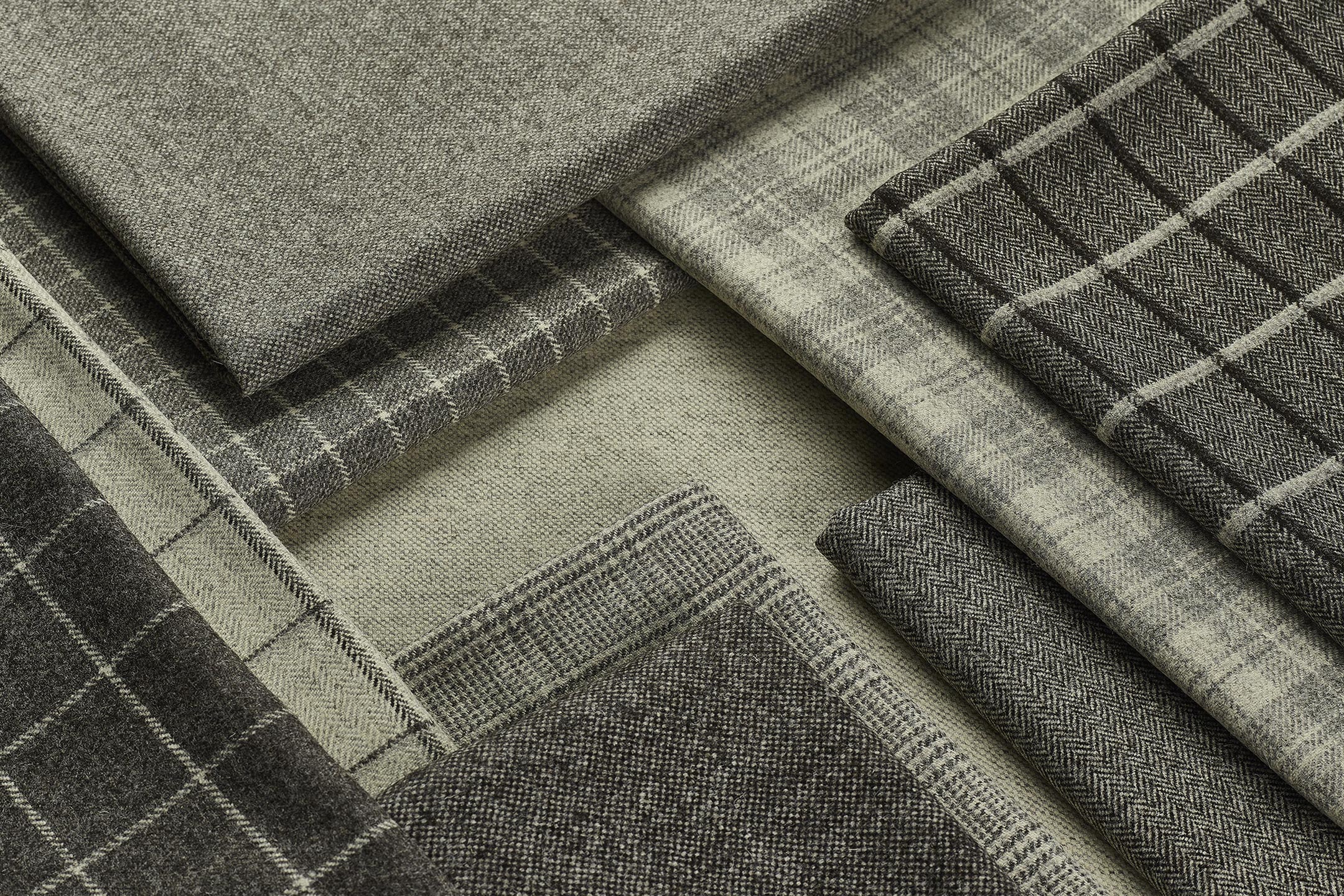

“The green, gold and silver 10z woollen cloth – the official SCG colours – was chosen not only because of its classic English drape and finish, perfect for formal jacket garments, but because of its lightweight characteristics, which is crucial given the warm Australian climate.”

Oscar Hunt crafted the first custom blazer for Ms Mather, the first female CEO of the SCG in its 160-year history. More cloth will be shipped across over the coming months.

“We’re extremely proud of our 123-year legacy in Huddersfield – a town well-known for producing the finest fabric in the world. And, knowing our cloth has been exclusively selected for this project is not only a celebration of Dugdale’s longstanding textile legacy but our hometown’s too,” Mr Glendenning said.

Once the cloth arrives from Huddersfield, Sydney-based Oscar Hunt take three fittings – in their showroom – from members interested in purchasing a blazer, with the whole cloth-to-garment process taking six weeks.